Login

Log in if you have an account

Register

By creating an account with our store, you will be able to move through the checkout process faster, store multiple addresses, view and track your orders in your account, and more.

Create an accountWipe the surface with a cloth

To properly care for the surface of the instrument, use a polishing cloth or other soft cloth to wipe away any human oils (such as fingerprints) and other dirt to the extent that you can reach.

Use the right oil in the right place

There are three types of oil that are used for the various parts of the rotary valves in horns, tubas, and other instruments: rotor oil, rotor spindle oil, and lever oil.

The slides use yet another type of lubricant, slide grease (not to be confused with slide cream).

Oil can improve the lubrication of moving parts, reduce noise, and prevent friction and rust. The appropriate oil to use in order to allow for the necessary clearances between moving parts on the instrument is different for different sections. In the moment, it may seem that applying any kind of oil might be fine and not lead to any problems, but over the long term, using the wrong oils in the wrong places is not good for the instrument.

The functions of the three oils

- Rotor oil is used for lubrication between rotor surfaces and their casings. Because these components are relatively large and their clearances are small in relation to their size, a light oil is used.

- Rotor spindle oil is for the rotor spindles. This oil is fairly heavy because it is used in a place with a small diameter where there is little contact with air from inside or outside, and also because it must aid the rotation of the rotor spindles.

- Lever oil is used for the lever rod and joints. Because these are areas where force is applied in one direction, it is easy for them to wear unevenly, so a rather heavy oil is used.

Rotor oil is light and dries quickly, meaning that it is not very effective when applied to rotor spindles or levers. If heavier oil like lever oil is used in a rotor, the rotor will not move as freely (or quickly).

Do your best to understand the nature of these oils and the components they are applied to and be intentional about which ones you apply where. Only apply specific oils where they belong. By doing so, you will avoid unnecessary trouble, and you can expect your instrument to have a longer life.

Other tools and supplies for care

In addition to these three types of oil, it is also good to have a mouthpiece brush for cleaning the inside of the mouthpiece, flexible cleaners or specialized swaps for cleaning the inside of the leadpipe, and a cleaning rod for the slide.

Apply oil to the rotors before playing

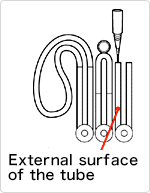

- Remove the slide, and then apply rotor oil to the rotors as shown in the diagram.

- Be sure to press the lever before removing the slide.

- To prevent the grease and dirt in the slide from mixing with the oil, do not touch the oil applicator tip to the outer surface of the slide.

- The tip of the oil applicator is made of metal, so when applying oil be very careful not to touch the rotor with it.

- Operate the lever to ensure that oil covers all parts.

Remove moisture from inside the tube after playing

- Remove the slide, and let the water out.

- Apply oil to the rotors as you did prior to playing.

- Wipe down the outside of the instrument using a polishing cloth. If dirt or discoloration is noticeable, use the cleaning materials described in the next section.

*Note: A silicon cloth after cleaning will bring out the original luster of the instrument.

Be gentle and patient when polishing lacquered surfaces

For polishing horns and other metal wind instruments, including the saxophone, polish that is appropriate for the specific material and finish of the instrument should be used. Lacquer polish should be used for instruments with a lacquer finish, silver plated instruments should be polished with silver polish, and metal polish should be used for instruments that have neither lacquer nor plating. Apply a small amount of the appropriate type of polish to a polishing cloth.

Since lacquer finishes are not very hard, they can be scratched up even just by wiping relatively gently with a polishing cloth. If there are any abrasive particles in the dust in the air, and those adhere to the surface of the instrument or get caught on the cloth before wiping, they can create scratches as well. The best way to wipe is to be gentle, applying only a modicum of pressure, and polish over a large area with a good amount of patience.

Using swabs

When using a swab to clean a horn, the process goes more smoothly if the swab is inserted from the wider end of the mouthpipe (the tube that the mouthpiece is inserted into). For both the first and second slides, the swab can be inserted from either end. Insert the swab weight-end first, and turn the instrument to help guide it through the pipe.

Once the weight comes out of the end opposite the end it was inserted into, the swab itself can be pulled through the length of the instrument's pipe by slowly pulling on the spindle end of the cord.

For the slides as well, insert the weight into the tube to send the string through until the place where the pipe turns, and then turn the slide upside down so that the other opening points downward, shaking the slide to bring the spindle downward and out the opening. Once the weight comes out of that end (the end opposite to where it was inserted), pull the cord to bring the swab through the tube.

There are two different types of swabs: S1 and S2. S1 swabs can be used on the first and second slides. They can be used on both F and B flat instruments. S2 swabs are for the mouthpipe.